Automation

Nunc iaculis nisi suscipit euismod semper. Donec placerat ante sed erat commodo finibus vitae quis est. Nam vitae varius velit.

PRODUX-Plus

PRODUX®-Plus is the state-of-the-art process control system of KHD Humboldt Wedag for operation of plants in the cement, coal and minerals industry.

Features

- Object wise scalable – one engineering tool for small application of 500 objects up to systems with 10 working places and 10000 objects

- System wise scalable – from small machine monitoring systems up to large production lines

- Modern software architecture

- Expandable – every time as needed

- Modernization, upgrading or Greenfield plants

- Compatible with control hardware from all the reputed manufacturers (Siemens, ABB, Schneider, Allen Bradley)

- SIMULEX® as add-on training tool uses the same system arrangement – look and feel like in a real plant

Benefits

Provides fast and safe control and supervision of the process by offering overall, comprehensive and detail display.

PRODUX®-Plus renders logging of process information, energy and mass balances, raw material and product inventories and other reports which can be adapted to a specific plant application.

Specs & Sizes

Nunc iaculis nisi suscipit euismod semper. Donec placerat ante sed erat commodo finibus vitae quis est. Nam vitae varius velit. Fusce elementum ante erat, at faucibus ante euismod vel. Sed pretium dui sem.

Combines With

Region Name

Persons Name

personname@khd.com

+12 34 5678 9101

Region Name

Persons Name

personname@khd.com

+12 34 5678 9101

No downloads or brochures currently available.

ROMIX

For more than 30 years ROMIX control systems have provided uniform raw meal quality in many countries of the world. Advanced adaptive computer control of raw meal composition with raw material identification and minimization of additive cost.

Features

- Production integrated quality assurance

- Production integrated environmental protection

- Economical benefit reduction of maintenance reduction of energy expenditures optimum exploitation of the utilised raw materials and intermediate products

- Improvement of work place quality

Benefits

ROMIX®-S

Fully automatic, representative sampling for all products and intermediate products of cement manufacturing.

ROMIX®-T

Sample dispatch (transport) by pneumatic tube system to the laboratory.

ROMIX®-P

Fully automatic or manual sample preparation for their analysis.

ROMIX®-A

Sample analyzing by means of X-ray spectrometer, crossbelt analyser, diffractometer (Rietveld), laser granulometer, etc.

ROMIX®-C

Computer-assisted, adaptive quality control of raw materials and raw meal including statistic methods for permanent identification of the composition of raw materials and optimizing methods e.g. for minimizing the cost of feed materials.

ROMIX®-Q

Laboratory data base as quality control basis in the cement works.

Specs & Sizes

Nunc iaculis nisi suscipit euismod semper. Donec placerat ante sed erat commodo finibus vitae quis est. Nam vitae varius velit. Fusce elementum ante erat, at faucibus ante euismod vel. Sed pretium dui sem.

Combines With

Region Name

Persons Name

personname@khd.com

+12 34 5678 9101

Region Name

Persons Name

personname@khd.com

+12 34 5678 9101

No downloads or brochures currently available.

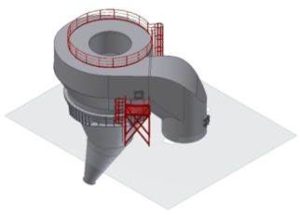

SCANEX

SCANEX® is the first infrared kiln shell diagnostic system and the most reliable one. More than 150 SCANEX® systems prevent worldwide extensive damages to rotary kilns and undesired loss of production.

Features

- No need for compressed air or cooling water

- Fouling effects automatically compensated

- Windows-based operator interface

- Maintenance-free operation

- Self-monitoring

- Robust

Benefits

Fusce elementum ante erat

At faucibus ante euismod vel. Sed pretium dui sem.

Donec sodales, urna ac tristique semper

Nunc justo feugiat dui, a rhoncus enim leo ut nulla. Mauris fermentum mi sodales eros vulputate egestas.

Quisque quis auctor nibh, quis sagittis tellus.

Donec ut arcu lobortis, mollis erat eget, lobortis tortor. Nam eu interdum turpis. Vivamus a urna arcu.

Better Longevity

Reduced wear by autogenous wear protection.

Specs & Sizes

Nunc iaculis nisi suscipit euismod semper. Donec placerat ante sed erat commodo finibus vitae quis est. Nam vitae varius velit. Fusce elementum ante erat, at faucibus ante euismod vel. Sed pretium dui sem.

Combines With

Region Name

Persons Name

personname@khd.com

+12 34 5678 9101

Region Name

Persons Name

personname@khd.com

+12 34 5678 9101

No downloads or brochures currently available.

MILLEXPERT

The expert system with fuzzy logic for automatic operation of grinding systems produces steady operation, optimizes quality, operating costs and production capacity.

Features

- Mauris fermentum mi sodales eros vulputate egestas, quisque quis auctor nibh, quis sagittis tellus.

- Donec ut arcu lobortis, mollis erat eget, lobortis tortor, nam eu interdum turpis.

- Vivamus a urna arcu, sed condimentum a massa in interdum.

Benefits

Results from plants with MILLEXPERT®systems:

8 % increase in production capacity

Reduction of electrical power requirements by 12 %

Guarantees the automatic start-up and shut-down of the entire grinding plant

Quisque quis auctor nibh, quis sagittis tellus.

Donec ut arcu lobortis, mollis erat eget, lobortis tortor. Nam eu interdum turpis. Vivamus a urna arcu.

Better Longevity

Reduced wear by autogenous wear protection.

Specs & Sizes

Nunc iaculis nisi suscipit euismod semper. Donec placerat ante sed erat commodo finibus vitae quis est. Nam vitae varius velit. Fusce elementum ante erat, at faucibus ante euismod vel. Sed pretium dui sem.

Combines With

Region Name

Persons Name

personname@khd.com

+12 34 5678 9101

Region Name

Persons Name

personname@khd.com

+12 34 5678 9101

No downloads or brochures currently available.

PYROEXPERT

This new generation of kiln automation is based on expert knowledge, fuzzy logic and a broad process know-how.

Features

- Mauris fermentum mi sodales eros vulputate egestas, quisque quis auctor nibh, quis sagittis tellus.

- Donec ut arcu lobortis, mollis erat eget, lobortis tortor, nam eu interdum turpis.

- Vivamus a urna arcu, sed condimentum a massa in interdum.

Benefits

Optimized kiln operation, enhanced productivity, uniform product quality combined with minimized fuel consumption result in pay-back times of 6-9 months.

Results from plants with PYROEXPERT®systems:

- Reduction of NOX emission by 15 %

- Reduction of SO2 emission by 11 %

- Increase of production throughput by 6 % at unchanged fuel and energy consumption

- Reduction of electric power requirement by 13 %

- More than 90 % availability of PYROEXPERT®

Quisque quis auctor nibh, quis sagittis tellus.

Donec ut arcu lobortis, mollis erat eget, lobortis tortor. Nam eu interdum turpis. Vivamus a urna arcu.

Better Longevity

Reduced wear by autogenous wear protection.

Specs & Sizes

Nunc iaculis nisi suscipit euismod semper. Donec placerat ante sed erat commodo finibus vitae quis est. Nam vitae varius velit. Fusce elementum ante erat, at faucibus ante euismod vel. Sed pretium dui sem.

Combines With

Region Name

Persons Name

personname@khd.com

+12 34 5678 9101

Region Name

Persons Name

personname@khd.com

+12 34 5678 9101

No downloads or brochures currently available.

PYROEXPERT

This new generation of kiln automation is based on expert knowledge, fuzzy logic and a broad process know-how.

Optimized kiln operation, enhanced productivity, uniform product quality combined with minimized fuel consumption result in pay-back times of 6-9 months.

Results from plants with PYROEXPERT®systems:

- Reduction of NOX emission by 15 %

- Reduction of SO2 emission by 11 %

- Increase of production throughput by 6 % at unchanged fuel and energy consumption

- Reduction of electric power requirement by 13 %

- More than 90 % availability of PYROEXPERT®

Contact One

Contact One